FlowBoard

Our offer for you

Optimizing granular flows is often not trivial. Simulations using the discrete element method are a suitable tool here, which also aids in understanding the process. In addition to the necessary simplifications of the particle shape or the contact laws used, the required model parameters play an essential role in realistically representing the process. However, determining the model parameters is not easy and requires extensive experience. The quality of the simulation can only be as good as the accuracy of the used input parameters. A frequent question about a simulation is therefore “Is what I see here correct?”

Based on a detailed experimental characterization of your granular material using specially developed tests, we determine the specific model parameters for your material by comparing experiments and simulations.

Together with recommendations for appropriate problem-specific modeling assumptions, this gives you the certainty that your simulations can be used effectively to solve your problem.

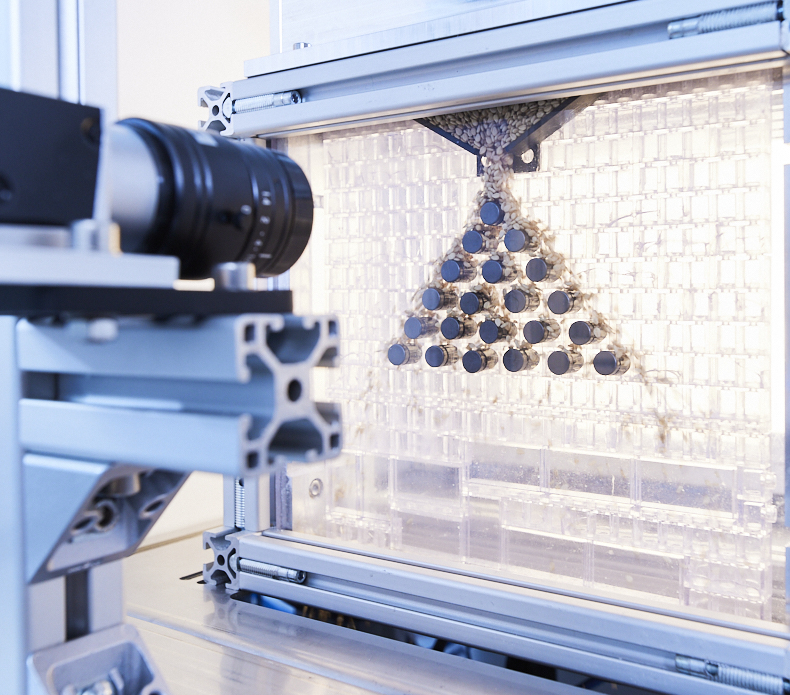

Characterization using the FlowBoard

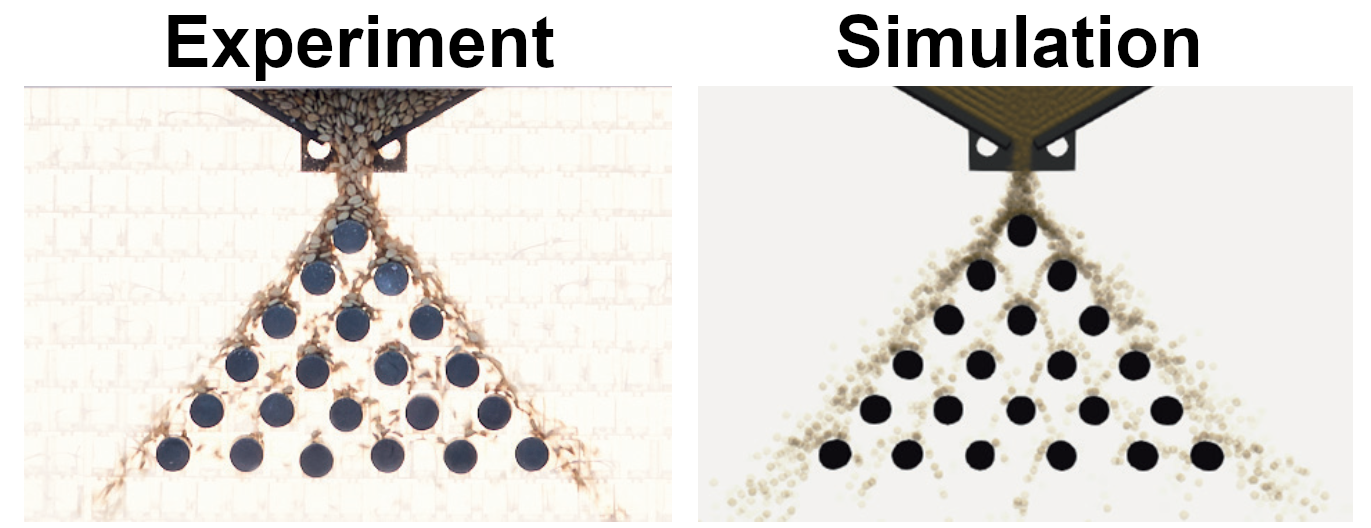

While some model parameters can be derived directly from the measured values, others must be adjusted using inverse simulation, i.e., the simulation of real tests. Here, our experience and a large data base help to limit the manual effort required. By comparing the experiment with the simulation, we then obtain the model parameters that are most suitable for your application.

The image shows a typical test setup for our patent-pending FlowBoard, which we use to determine discrete element model parameters. The FlowBoard allows us to record many characteristics of the powder flow simultaneously in tailored obstacle courses. This apparatus enables us to calibrate a multitude of model parameters with a small number of experiments.

Varying the used obstacle course allows us to focus on different particle-particle or particle-wall properties, such as friction, cohesion and restitution. Depending on the course design, we examine either dense granular flow behavior or collision behavior of isolated particles.

What you will receive from us

The image on the left compares the powder flow pattern in the FlowBoard with the respective simulation results. This comparison confirms that the flow behavior of the granular material observed in the numerical simulation corresponds to its behavior in reality.

At the end of the project, you will receive a report in addition to the model parameters themselves. The report describes the contact models used and all assumptions made in the discrete element simulation. You will also receive still images and videos of both the experiment and the corresponding simulation.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM