Additive manufacturing: Creating reliable parts

Introduction

Additive manufacturing processes currently penetrate both science and industry. These methods provide specific advantages including the customization and complexity of manufactured components. Additively manufactured components are already utilized in complex systems, for example airplanes. However, the reliability of these types of components is not yet satisfactory for use in structural lightweight parts. Nonetheless, additive manufacturing methods enable the production of highly complex parts with customized mechanical properties at minimal weight.

The task

Fatigue of additively manufactured parts is on the one hand determined through surface roughness, typically in the range of Rz = 25 to 40 µm which is significantly larger than in traditional forming processes using gravity die casting (Rz = 3 to 8 µm). Systematic monitoring of the roughness would therefore be desirable; however this is currently not possible. On the other hand, a locally occurring residual porosity as well as layers which have not merged after melting can cause component failure. Simulation tools can help to identify relevant process parameters and to monitor and consequently make possible the production of reliable components.

At the moment, no established simulation tools exist for additive manufacturing. The availability of a continuous process simulation would be useful in view of the complexity of the processes to fulfill requirements for form and structure within the product development cycle. SimPARTIX® offers various numerical methods which make possible process simulations for additive manufacturing. These include simulating the spreading of powder yielding packing densities which influence the dynamics of the melting process as well as simulations of melting and resolidification which determine the porosity, the surface properties and finally the strength of the component.

Results

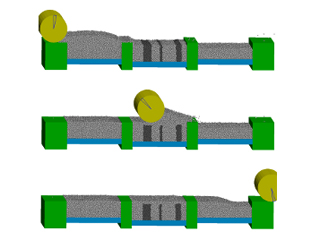

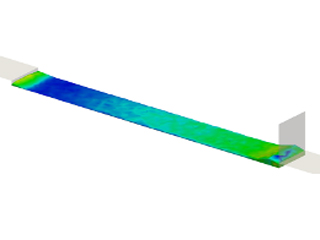

The density distribution of a new powder bed layer is shown in the adjacent figure. This is one possibility to analyze a discret element simulation of the spreading process. Alongside investigations concerning the homogeneity of the powder bed density, anisotropic attributes can also be analyzed through spatial orientation of the grains. The simulations allow extensive studies of the effects of powder characteristics and process parameters on the properties of powder beds, which are relevant for further process steps.

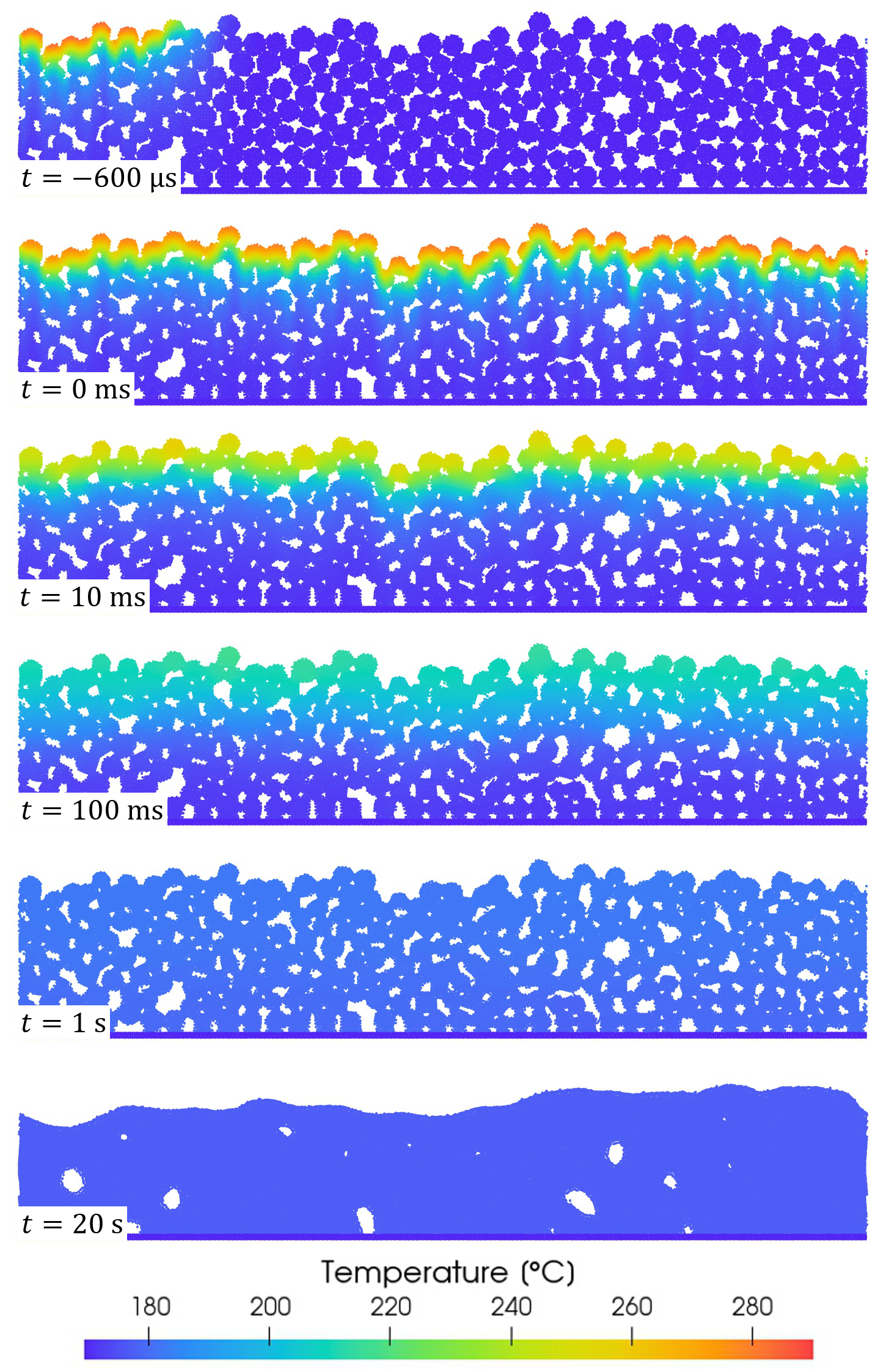

Smoothed Particle Hydrodynamics simulations are carried out for the actual melting and solidification process during laser powder bed fusion (LPBF). The results of a 2D simulation of a single laser track using polyamide 12 (PA 12) particles is shown in the adjacent figure. The laser moves until along the sample is then turned off. While the laser traverses the particles negligible thermal diffusion occurs. Then, the temperature field becomes more and more homogeneous in combination with cooling from the bulk. On the largest time scale densification due to fusion of the particles takes place. A surface roughness profile at the final stage is observed which can be related to the initial particle positions. Furthermore, some pores between the particles do not completely vanish.

From this simulation it can be deduced that the process includes three time scales. First, a laser irradiation time scale of the order of hundreds of microseconds, second, a thermal diffusion time scale of the order of hundreds of milliseconds, and third, a viscous flow time scale of the order of seconds exist.

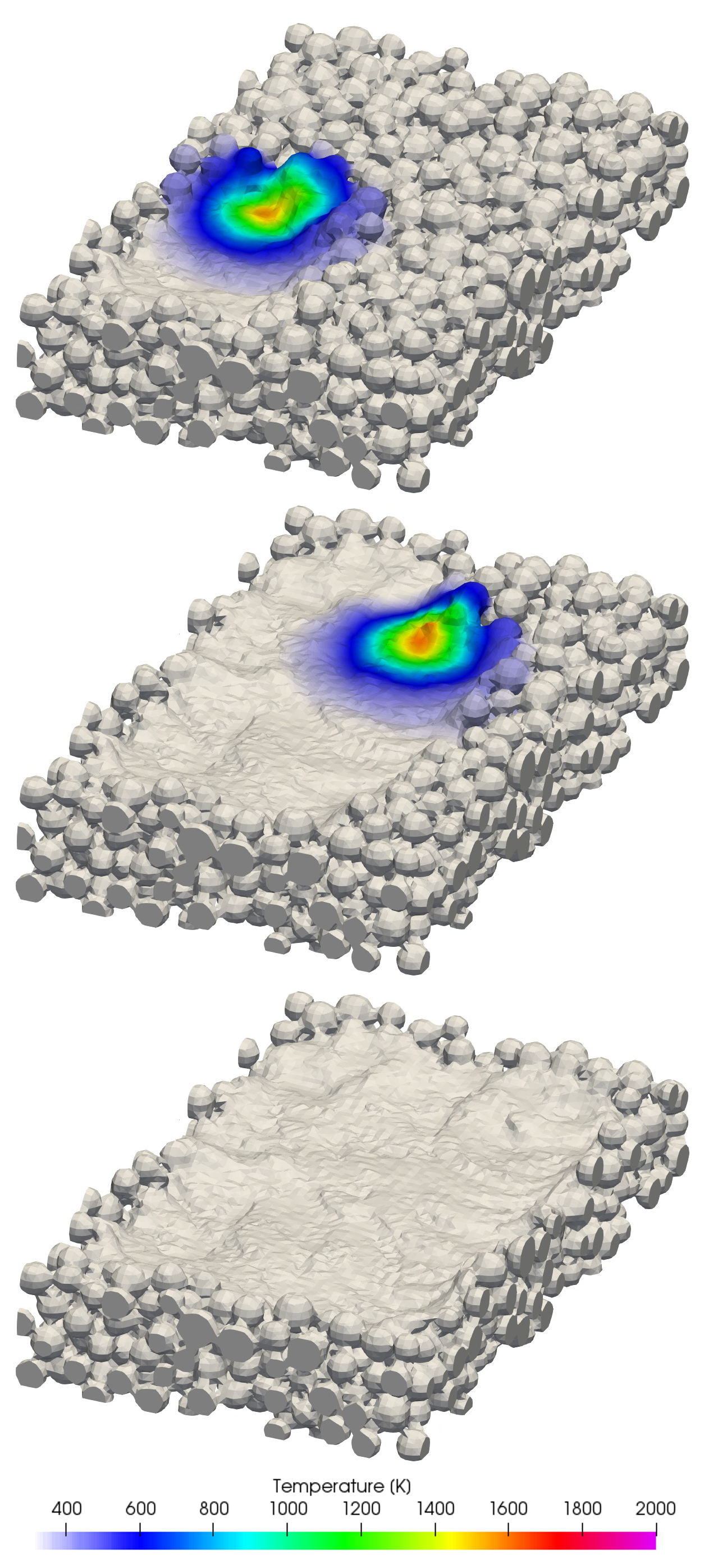

3D simulations of melting and re-solidification can also be performed for metal powders. The figure on the left shows a laser beam traversing three adjacent tracks. The powder particles are melted along the laser tracks. The flow behavior is influenced by gravity and surface tension. Of particular relevance here is the temperature dependence of the surface tension, which causes so-called Marangoni currents.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM