Screen printing of ceramic multi-layer circuits

Introduction

Ceramic multi-layer circuit boards (so-called low-temperature co-fired ceramics, LTCC) can be found in microwave circuits, technical medical appliances (e.g. pacemakers), sensors, transmitters, receivers and WLAN equipment, to name just a few products. The tracks at the micrometre scale, resistors and other components are located on ceramic tapes packed tightly on top of each other.

The fine tracks are printed on the boards using the screen printing technique. To do this, a metal paste containing fine aluminium or silver particles is pressed onto a surface via a template with the desired form and afterwards sintered together with the ceramic films at a relatively low temperature.

The task

A research project entitled NanoSieb (ref. No. 02PG2291; project management: Forschungszentrum Karlsruhe) was set up by the Federal Ministry of Education & Research in order to improve the peeling behavior of the paste from the mesh by using hydrophobic mesh coatings, which would in turn enable the print resolution to be improved.

However, at the start of the project it was not yet known what properties a coating on the mesh surface would need in order to improve the print resolution and to what extent it would be necessary to adapt the existing paste systems. Therefore, instead of expensive trial-and-error tests the Fraunhofer Institute for Mechanics of Materials IWM was appointed to design a simulation model based on SimPARTIX® so that the entire screen printing process could be modeled on the computer. This simulation model would then be used to carry out specific parametric studies in order to save time in the development of coatings and suitably adapted pastes.

Results

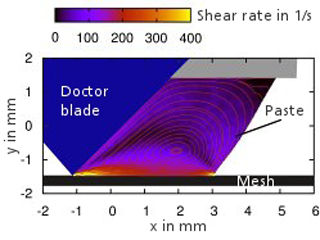

The model for screen printing pastes developed in this project on the basis of SimPARTIX® makes use of smoothed particle hydrodynamics (SPH). To do this, the SPH method was extended to such an extent that pseudo-plasticity (reversible fall in viscosity as the shear load rises) and thixotropy (change in viscosity after a delay with respect to shear load) could be simulated. The model parameters were determined by comparing them with experimental data supplied by project partner Dresden University for a silver reference paste from Heraeus. There was good agreement.

Together with a multi-phase model that takes into account the wetting behavior of the paste on the mesh, SimPARTIX® was then able to be used to develop a simulation model for the complete modeling of the screen printing process. Owing to the large scale differences in screen printing, a multi-stage approach with the representative simulation geometries for each stage was set up in order to investigate how various process parameters influence the flow behavior of the paste during the blade movement, during filling of individual screens and during the peeling process.

The flow behavior of the paste was investigated in detail in the simulations. It was shown that a hydrophobic coating on the underside of the mesh clearly improves the peeling of the paste. At the same time, it was discovered that a separate coating on the top of the mesh is unnecessary. In addition, the rheological properties required by the paste were also derived. This considerably simplified the development of suitable coated meshes and matching pastes for the industrial partners and in the end led to track widths being reduced from approx. 80 µm to 20 µm.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM