Tape casting: production of ceramic tapes

Introduction

Tape casting is a primary forming method used for the production of thin, wide ceramic tapes. The raw material for this is the ceramic powder, which is mixed with solvents and additives to form a free-flowing casting slurry.

The forming process takes place in the tape casting plant, where the ceramic slurry is spread continuously over a conveyor belt with the help of a doctor blade to form a flat, even layer. This layer of slurry is subsequently dried and coiled ready for further processing.

Such tapes are used, for instance, as circuit boards in integrated multi-layer circuits, e.g. for so-called LTCC (low-temperature co-fired ceramics) circuits.

The task

The production of integrated multi-layer circuits, especially multi-layer LTCCs, calls for tight manufacturing tolerances; the tendency for the tolerances to be dependent on the batch should be minimal. Optimization of the production process with respect to these factors, and hence an improvement in product quality and reproducibility, requires a profound understanding of the various steps in the process and the associated influencing variables. It is essential to correlate the various process and material parameters with the properties of the tape, which determine the final product. The parameter space here is very large, and so, for example, the rheological behavior of the casting slurry can be attributed to the interaction between the individual slurry components at the microscopic level. The macroscopic factors, e.g. plant geometry or belt speed, in turn have an influence on both the form of the tape and its microstructure.

Two projects for simulating the tape casting process have been carried out at the Fraunhofer Institute for Mechanics of Materials IWM:

The SimFol project promoted by the Federal Ministry of Education & Research (ref. No. 03X0508C; project management: PtJ Forschungszentrum Jülich) in cooperation with Kerafol, Heraeus and VIA electronic, in which the focus was on improving the quality and productivity of the tape casting process.

The research project of the Deutsche Forschungsgemeinschaft (DFG) Experimental studies and simulation of anisotropy development during tape casting and the drying of ceramic tapes (KR 1729/9-1), in cooperation with the Institute for Materials Science of the Friedrich Alexander University of Erlangen-Nuremberg, in which the main focus was research into the factors that affect the alignment of the ceramic particles in the tape.

Results

The simulation allows users to study the tape casting process at various scales and to determine the effects of the individual variables on the properties of the tape by means of parametric studies.

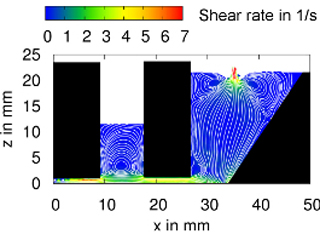

The SimPARTIX® SPH model provides a chance for a multi-scale approach to this simulation of the tape casting process. On the one hand, it can simulate the flow within the slurry chamber, taking into account the complex casting slurry rheology, and hence show – in three dimensions – how the chamber geometry influences the flow profile.

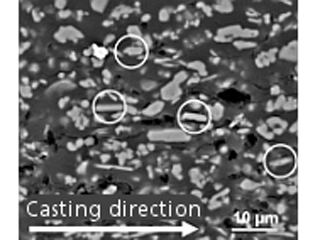

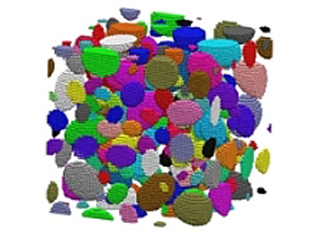

On the other hand, an expanded SPH model can be used to calculate the slurry behavior at the microscopic level. To do this, the individual components of the suspension and their interactions with each other are simulated directly. It is therefore possible to investigate effects such as how the shape of the ceramic particles affects the anisotropy in the green film microstructure or the viscosity of the suspension.

The flow within the casting plant was simulated in two and three dimensions in the course of the aforementioned projects. How changes to the slurry chamber geometry affect the flow situation were also examined. Further, the results of the simulation were compared with those from tests carried out on industrial casting plants by the project partner Kerafol. There was good agreement between the simulation and the real process.

At the microscopic level the simulation was able to illustrate and quantify the relationship between particle form and particle alignment. Here again, there was good agreement with the experimental results. The microscopic model will be developed further in the course of the DFG project so that it is possible to model suspensions more accurately and hence discover how all the relevant parameters affect the behavior of the slurry under shear.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM