Minimizing erosive wear

Introduction

Erosive wear occurs in many processes involving particles which hit a wall with large relative velocities. Even though the material removal for each impact is very small the collective damage is often significant. The erosion can be augmented if sharp-edged particles are used.

If the eroded surface is not visible because it is an inner surface the effect might be noticed too late sometimes. In the worst scenario a hole is already formed. The following down time and the maintenance effort cause high cost and should be avoided if possible. An early detection of erosive areas by regular inspections is one suitable measure of precaution.

Particle-based simulations are a useful tool in order to prevent erosive wear right from the start. The simulations are able to describe the granular mass flow and to capture individual impact events. By means of calibrated erosion equations the material removal can be inferred from kinetic details of each impact. The gained knowledge can be used to minimize erosive wear by constructional modifications or targeted material substitutions.

The task

Material removal by cutting occurs especially for shallow impacts with small angles of incidence and sharp-edged particles due to the transferred kinetic energy. For normal impacts on the contrary, surface cracking for brittle materials and deformation wear for ductile materials are the predominant erosion mechanisms.

The active wear machanisms depend on the type of particles as well as the eroded material. In order to identify the mechanisms and to quantify the amount of wear, controlled erosion experiments can be conducted at the Fraunhofer IWM. The grain velocity as well as the angle of incidence on the material surface are varied thereby. The eroded volume is then precisely measured using a three-dimensional laser scanning microscopy technique.

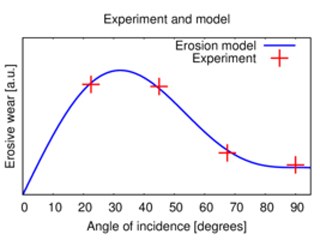

The figure shows exemplary the erosive wear normalized to a single grain impact as a function of the angle of incidence. The pronounced angle dependence becomes apparent. An analytical function is fitted to the experimentally obtained data. The characteristics of the function are physically motivated by underlying erosion mechanisms. Based on the experimental calibration, the function can be used to quantitatively predict the erosive wear in particle-based simulations.

Results

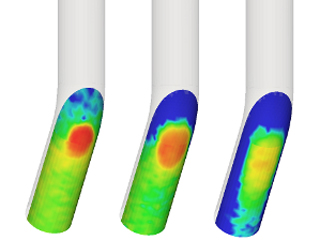

SimPARTIX® simulations keep track of the erosive wear of a surface caused by individual impacts using underlying erosion equations. For visualization purposes so-called heat maps can be generated from this data. The figure on the left displays the wear in a bent pipe which is caused by particle impacts due to gravity. Clearly discernible is the rea area of primary particle impact. But also further wear along the surface exists. Nearly no erosion occurs in the blue areas.

SimPARTIX® offers the simulation of multiple-phase flows and, thus, the erosive behavior of a suspension. Coupled DEM-SPH simulations are used for this purpose. The figures in the center and on the right, respectively, display the erosive wear caused by particles suspended in fluids with different viscosity. The the overall wear decreases with increasing viscosity. The viscous properties of the fluid dampen the particle motion causing them to hit the surface with less kinetic energy.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM