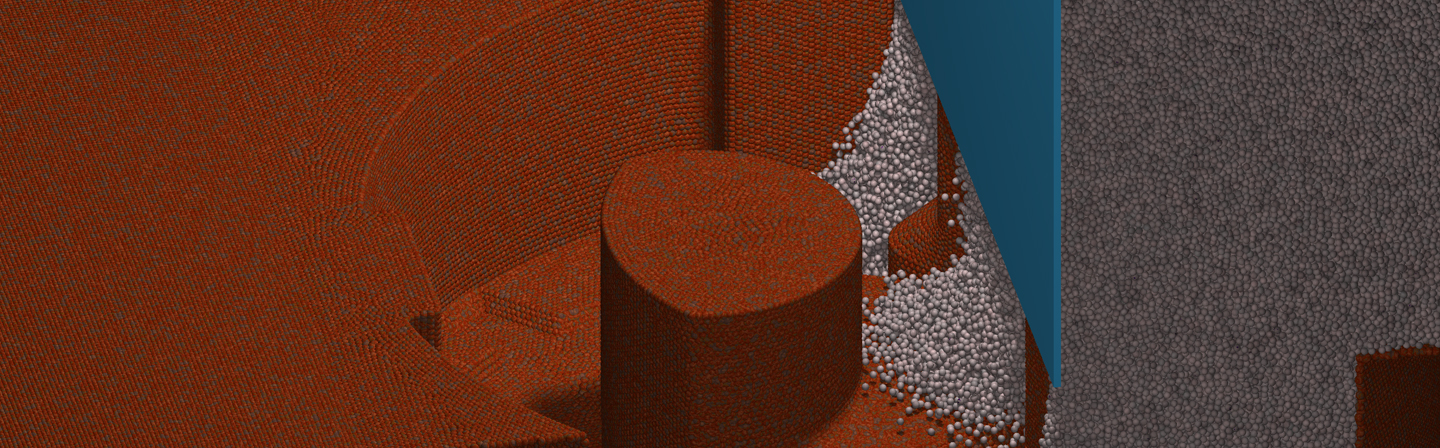

SimPARTIX® stands for our competence in modeling the mechanics of materials and fluids using mesh-free methods.

SimPARTIX® is also an innovative and powerful simulation tool developed at the Fraunhofer IWM.

Based on physical models, SimPARTIX® is used to investigate various materials in manufacturing processes and in service. This typically generates a large amount of data on the dynamical material behavior. By means of detailed analyses and visualizations of the data we provide in-depth insights into the fundamental dynamics of your processes. SimPARTIX® can therefore help you to grasp a full understanding of your applications and yield design specific optimization measures.

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM